Photo Journal: RDC Arctic Technology Evaluation 2017

The Coast Guard Research and Development Center is conducting its annual operation in the Arctic, Arctic Technology Evaluation 2017, aboard Coast Guard Cutter Healy and in conjunction with District 17’s annual Arctic Shield exercise. During the deployment, the RDC staff will conduct extensive research and technology evaluations to support the Coast Guard’s Arctic strategy of promoting safe, secure and environmentally responsible maritime activity in the region. Additional details about Arctic Technology Evaluation 2017 can be found here.

Aug. 12, 2017 – Port of Seward, Alaska. After spending the past few days packing, cleaning and preparing to disembark, the final duties for the RDC’s Arctic Technology Evaluation 2017 are being completed now that Coast Guard Cutter Healy has arrived at port. Quarters are conducted on Healy’s flight deck, with Capt. Greg Tlapa giving out awards to departing crewmembers and discussing the upcoming voyage. Scot Tripp, RDC chief scientist for the deployment, also thanked the crew for their professionalism and assistance.

Aug. 11, 2017 – Approaching Seward, Alaska. Two MH-60T Jayhawk helicopters from Air Station Kodiak, Alaska, transport Vice Adm. Charles Ray, deputy commandant for operations; Rear Adm. Michael McAllister, commander, 17th Coast Guard District, which consists of Alaska and the Arctic; and Reps. Duncan Hunter (R-Calif.) and Garrett Graves (R-La.) to Coast Guard Cutter Healy. While aboard, the congressmen received a tour and briefing discussing the strategic value of science operations for the Coast Guard in the Arctic. Hunter is chairman and Graves a member of the House Subcommittee on Coast Guard and Maritime Transportation.

Ray (center) talks with Healy crewmembers BOSN Justin Young (right) and BM1 David Edelson.

McAllister speaks with Holly Wendelin, command, control, communications, computers, intelligence, surveillance and reconnaissance (C4ISR) domain lead for the Coast Guard Office of Research, Development, Test and Evaluation.

Aug. 10, 2017 – Transiting toward Seward, Alaska. RDC team members Jason Story and Patrick Ryan lead a 3-D printing class for Healy’s crew. The class included examples of how 3-D printing can be used, materials and software needed to print, manufacturing basics, and instructions on how to 3-D print an object.

Aug. 6, 2017 – Nome, Alaska. Coast Guard Cutter Healy is anchored off Nome; missions include unmanned maritime system (UMS) and beach transfer boat evaluations as well as transfer of some personnel to shore. Scot Tripp, the RDC’s chief scientist for the cruise, remotely pilots the unmanned maritime system in the background, using the virtual reality system that was incorporated onto the system.

Healy crew members were given the opportunity to pilot the UMS from the fantail of the ship to let them experience operation of an unmanned system. The UMS was put in remote control mode and participants used virtual reality glasses for the experience. SA Jacob Molina (left) is one of many who piloted the UMS, here under the watch of Lt. Carlon Brietzke of the RDC.

Those not assisting in the scientific evaluations were granted liberty while Coast Guard Cutter Healy was at anchor. While in Nome, Lt. j.g. Hessamoddin Shafeian of the RDC team met with residents who regularly use their boats for fishing and hunting. A native of the area expressed that he does not use the Automatic Identification System (AIS) or other electronics for his expeditions because they are too expensive. After hearing more about how AIS can aid mariners, this Alaska native expressed an interest in an affordable, compact version and recommended the technology be accessible through personal cell phones. A current RDC project is already developing this technology, proving that the RDC AIS project “reaches beyond military and commercial vessels and into the everyday life of all citizens.”

Aug 5, 2017 – Nome, Alaska. Evaluation of the shore transfer craft commenced once Healy was anchored off Nome. The boat is lowered from the flight deck to the starboard side of the ship via crane. RDC team members Mike Coleman and Jason Story designed and printed improved steering control components for the vessel. The boat conducted a successful beaching and crew members disembarked; however, the craft took on encountered several waves while beached, which caused some technical difficulties. A cutter boat-large (CB-L) helped with the return to Healy and the RDC team will troubleshoot the system for future operations.

Before anchoring in Nome, a Coast Guard MH-60T helicopter from the forward operating location in Kotzebue, Alaska, conducted primary tie landings, a touch and go, and a hot gas refuel in addition to delivering personnel to Healy. The operations are necessary to keep both cutter and helicopter qualifications current.

Aug. 4, 2017 – Transiting toward Nome, Alaska. Coast Guard Cutter Healy has departed from the ice fields of the Arctic, after traveling well into the 75th latitude. While consistently encountering ice of this nature, the icebreaker did not face any large continuous ice or multi-year ice. Some chunks did display signs of ridging, which indicates that at one point the ice was blown tight and piled upon itself.

Healy is one of five Coast Guard cutters participating in an RDC project to evaluate the potential applications of additive manufacturing aboard cutters. During this cruise the RDC team provided additional training in 3-D printing and the associated modeling software. Mike Coleman, the RDC test director, observes the printing of another 3-D part in support of RDC operations.

“Almost all of the projects have benefitted from the use of additive manufacturing during this trip,” says Jason Story, an RDC team member and the 3-D printing project manager. Several of the unique technologies being tested rely extensively on additive manufacturing, and several items were developed and 3-D printed to solve problems seen during testing. “Having the ability to make modifications to existing parts allows the team to quickly develop new prototypes and explore new ideas,” Story says. The servo arm (insert) of this unmanned maritime system was 3-D printed using nylon and carbon fiber, making it very strong yet lightweight.

A close-up of fin protectors designed to provide additional protection while transporting the unmanned underwater system during boat operations.

Aug. 3, 2017 – Chukchi Sea. A cutter boat-large (CB-L), shown prior to its launch from Coast Guard Cutter Healy, was used both for conducting an unmanned underwater system (UUS) operation and in recovering a scientific buoy for the National Oceanic and Atmospheric Administration (NOAA). During the boat transfer, the UUS is housed in improved protective cradle supports (the green components) that were 3-D printed by the RDC team.

UUS operations included two pre-programmed missions in autonomous mode. After a minor ballast issue, the first mission ran smoothly. The second mission began with good submerged propulsion but experienced a technical difficulty that curtailed UUS operations for the day. The RDC team notes that the short pre-programmed missions represent a big step forward with this technology; once pre-programmed operations are consistent, sensor integration for Coast Guard mission application will begin.

The CB-L tows and guides the NOAA buoy over to Healy’s fantail for recovery by the crew. Retrieval of this buoy requires special intricacy to avoid disrupting the complex instrumentation along the 2,500-foot buoy mooring chain, which stores more than a year’s worth of data. BM1 David Edelson says of the buoy recovery: “Today’s evolution is an example of the unique science operations we do on Coast Guard Cutter Healy. The methods to recover the buoy, we have to think of safe and effective ways to accomplish the evolution. Today’s recovery went amazing.”

Aug. 2, 2017 – Beaufort Sea, transiting toward the Chukchi Sea. Eric Schmid, a naval architect with the Surface Forces Logistics Center in Baltimore, is aboard Coast Guard Cutter Healy to study shipboard operations, assess general arrangements and conduct crew interviews in support of the new heavy polar icebreaker program – all to ensure the technical requirements of the new icebreaker consider lessons learned from previous assets with similar operating profiles. Schmid (inset) measures the ship’s structural vibration readings using a triaxial accelerometer and vibration analyzer. The purpose is to assess how ice breaking induces ship vibrations; while some readings were collected, Healy did not encounter any multiyear ice or very large ice floes on this cruise. “The new polar icebreaker is a high-visibility acquisition and an asset that will be expected to last for several decades,” Schmid says. “We are looking at every aspect to ensure mission effectiveness and sustainability goals are met over the life cycle of the cutter.”

The RDC team began assembling a Coast Guard skiff in support of its shore transfer craft evaluation. Crewmembers of cutters that operate in the Arctic often note the need for a craft to transport personnel and supplies to or from unimproved shore, especially when weather prohibits a helicopter transfer. The shore transfer craft could provide an option for communities that are not accessible by existing cutter boats, and its electric motor precludes the need to carry gasoline. “The craft was assembled relatively quickly and was fairly simple,” says Lt. Carlon Brietzke, “and we’re looking forward to testing this new capability once we arrive in Nome, Alaska.”

Aug. 1, 2017 – Beaufort Sea. RDC team members Patrick Ryan and Lt. Carlon Brietzke add a new rear-facing water-resistant camera to a mounting bracket they 3-D printed for the unmanned maritime system (UMS). Another goal of the team is to set up a live video feed over the MPU-5 network radios. “Work continues to build the capabilities to transmit live video over longer distances as part of our long-term plans for the UMS,” Ryan says.

The Coast Guard dive team continued dive operations, performing a running gear inspection of the ship’s propellers and rudders. The RDC team is using a remotely operated vehicle (ROV) to view divers, providing a second set of eyes in the water (inset shows the ROV before launch). This deployment marks the first dive directly off Coast Guard Cutter Healy in 11 years. The running gear inspection revealed only minor marine growth fouling on the propellers.

July 31, 2017 – Beaufort Sea (approximately 900 nautical miles from the top of the world). The RDC team continues evaluation of the unmanned maritime system (UMS), putting it into autonomous mode for the first time during the deployment. The UMS operator preprogrammed a mission using a laptop, and the UMS followed the correct path. The RDC team will continue to expand the system’s autonomous mode capabilities, including refinements to increase accuracy and fine-tune controls. In other testing, RDC intern Christian Welch – part of the DHS Science and Technology Directorate’s Science, Technology, Engineering and Math internship program – pilots the UMS via radio control mode, aided by the system’s real-time video feed.

Although the UMS is not designed for ice operations, its maneuverability allows it to easily pass through drifting ice floes in radio control mode. These capabilities also aided in easy recoveries off the stern of Coast Guard Cutter Healy with a special cradle constructed by the RDC team.

The Coast Guard dive team conducted an ice dive from the starboard side of Healy on the third straight day of successful ice diving operations. “It was awe-inspiring, and the colors were incredible,” says DV1 David Bradbury, a diver for Coast Guard Regional Dive Locker Pacific. “I wasn’t thinking about the cold temperature.” For the first time on this cruise, a remotely operated vehicle (ROV) launches with the shipboard deployment of divers to provide an extra set of eyes to ensure diver safety. The operator controls the ROV from inside the ship – out of the weather (inset photo). Imagery of the divers in the Arctic was recorded. ROVs will be a standard part of ship-based dives on Healy.

July 30, 2017 – Beaufort Sea. Coast Guard personnel launch an expendable bathythermograph, a data collection probe, from the fantail of Coast Guard Cutter Healy. The expendable bathythermograph measures temperature at various depths to help model the speed of sound throughout the water column. The data allows Healy’s crew to correctly calibrate the ship’s high resolution ocean floor mapping sonar software.

After a control rudder on an unmanned underwater vehicle broke during testing, the Healy crew 3-D printed a replacement (right) based on one of the spare parts (left). “While we had spare rudders, we took the opportunity to model and print a new blade on the 3-D printer to ensure we kept adequate stock onboard,” said Lt. Carlon Brietzke, who helped with the rudder repair. The Coast Guard is exploring a wide variety of applications for 3-D printing. During the 2017 Arctic Technology Evaluation, the RDC trained crewmembers from Healy to use the printer. The crew will continue to look for opportunities to use the technology throughout their remaining science cruises this year.

July 29, 2017 – Beaufort Sea. An unmanned maritime system (UMS) built by the Research and Development Center returns to Coast Guard Cutter Healy after testing. The system was designed to test unmanned sensor and video capabilities from long distances. Previous communications tests have demonstrated a range of 70 miles from its host ship. Christian Welch – an intern through the DHS Science and Technology Directorate’s Science, Technology, Engineering and Math internship program – piloted the UMS. The RDC also continued testing with an unmanned underwater vehicle.

An oil skimmer trails behind Healy during testing. The skimmer was able to maneuver well, but techniques to break up the ice to free potentially trapped oil will require further development.

July 28, 2017 – Beaufort Sea. The crew of Coast Guard Cutter Healy prepares to deploy a scientific buoy for the National Oceanic and Atmospheric Administration. The buoy will provide weather data that will help Healy’s crew make forecasts, and test innovative sensors that will improve climate observation in the Arctic. The deployment was also used as an opportunity to test the InstantEye small unmanned aircraft system (sUAS). The InstantEye captured video and photographs of the deployment.

July 27, 2017 – Near the Bering Strait. The RDC unmanned underwater system (UUS) team, including Jason Story and Patrick Ryan, troubleshoot Wi-Fi connectivity issues with the system. “We have restored the UUS to operational status,” Ryan says. “After troubleshooting the Wi-Fi connection, we fixed it by replacing related internal wiring.” Follow-on testing will be conducted at the next opportunity.

July 26, 2017 – Bering Sea. RDC staff members Patrick Ryan, Jason Story and DHS S&T STEM intern Christian Welch prepare to launch the unmanned underwater system (UUS) from the cutter boat during testing of its launch and recovery. A WiFi connection was initially established, but the UUS was not able to carry the connection long enough to execute a pre-programmed mission. Ballast testing was successful. The UUS team is troubleshooting the connectivity issue.

The RDC is developing a long-range broadcasting system that uses Automatic Identification System (AIS) transmission capabilities in Alaska to disseminate timely electronic safety information such as AIS data, weather, ice edge, distress signals and electronic chart updates. The RDC is leveraging existing Coast Guard infrastructure in Alaska and commercial-off-the-shelf products to install and test Digital Radio Mondiale equipment (Mondiale means worldwide in Italian and French). The information is transferred through High Frequency (HF) radio signals to Coast Guard Cutter Healy, and is then converted to a stream of data packets that are processed and displayed by a dedicated mobile device. Science team members tested access to the data using their cell phones (above); access was simple and loading speed was impressive. “It was exciting to read the latest news, AIS info and weather forecast on our cell phones while taking advantage of virtually no onboard satellite telecommunications infrastructures, just the HF radio gear the RDC has installed during the project,” says Lt. j.g. Hessamoddin Shafeian, who conducted the testing.

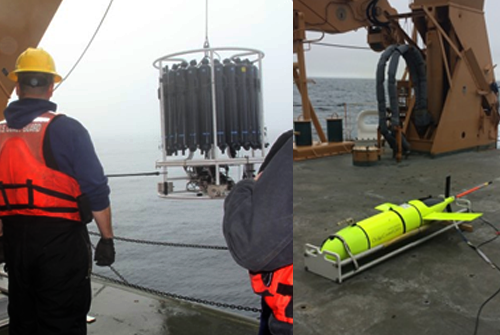

An oculus glider (right) was successfully deployed for the National Oceanic and Atmospheric Administration (NOAA). The glider will capture oceanographic data and test autonomous technology for ecosystem research in the Arctic and Bering Sea. “The Healy crew did an exceptional job of deploying the glider, and pilots at the Pacific Marine Environmental Laboratory in Seattle were able to confirm several successful dives while we were on site,” says Lt. Dan Langis of NOAA Corps. (Left) Healy crew members conduct a conductivity, temperature and depth cast at the deployment site, which “captured samples of sea water at various depths and will be used for data verification of the instruments onboard the glider,” Langis explains.

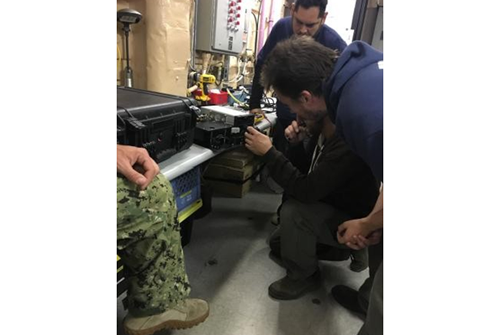

July 25, 2017 – Bering Sea. Remotely operated vehicle (ROV) operations in support of the Marine Board of Investigation inquiry of the fishing vessel Destination were completed this morning. The dive team, led by DV2 Adam Harris of the Coast Guard Dive Team San Diego, Regional Dive Locker West, used the ROV through the night to obtain imagery of the wreck site. “Overall ROV operations were challenging due to the environment,” says Harris, who was also the ROV pilot. RDC personnel and the Healy’s electrician’s mate repaired the ROV to overcome power, electronics and topside control box issues and the team used different techniques to mitigate the undersea current. “It was definitely a challenging mission where we had to think outside the box, but we were able to come together as a team to achieve the goals we set out to meet,” Harris says.

Members of the National Strike Force team troubleshoot the oil skimmer in response to difficulties with the hydraulic hose and sheet spotting the day before. A thorough inspection revealed no holes or punctures in the hoses, but during a dry run a fluid was observed coming from the discharge pump and thruster. The skimmer team has hypothesized that it is residual fluid or material remaining from the manufacturing process. The RDC is also working to create a support bracket system to better consolidate the 11 hydraulic hoses.

July 24, 2017 – Bering Sea north of St. George Island. Operations kick off on day four of the Coast Guard Cutter Healy voyage. The oil skimmer team – led by Lt. j.g. Hessamoddin Shafeian and including members from the Coast Guard Pacific, Atlantic and Gulf Strike Forces – launches the Aqua-Guard oil skimmer into the water off the fantail of the ship with help from Healy crew members. The blue sheath contains the 11 control hydraulic hoses. The test was terminated because of high seas and heavy hoses. “Due to difficulties with the hydraulic hose, skimmer operations will continue at a later date in the ice,” Shafeian says. The planned launch of the unmanned maritime system was also postponed due to rough sea conditions.

Members of the joint Coast Guard and U.S. Navy Dive Team board the landing craft polar vessel with Healy crew to travel to the wreck believed to be the fishing vessel Destination. A remotely operated vehicle (ROV) was used to try to obtain imagery of the vessel for a Coast Guard Marine Board of Investigation inquiry, but operational issues prevented reaching the wreckage. Information obtained on this mission will inform ROV operations tomorrow.

July 23, 2017 – Bering Sea. As the Healy travels to its first destination, the RDC team prepares for one of the early evaluations, the unmanned maritime system (UMS) evaluation. Lt. Carlon Brietzke and Jason Story are assembling a rigid cage to safely launch the UMS from the Healy. “The purpose of the UMS project is to develop a fully autonomous system capable of employing a variety of different sensors and instruments to carry out Coast Guard missions,” says RDC intern Christian Welch, who also is working with the UMS project. “Before fully autonomous operation can be achieved, we need to make sure the overall design, including propulsion and steering systems, are adequate for the intended missions. The easiest way to test this is by manually ‘driving’ the system.” Toward that goal, the day was spent refining the electronic controls and sealing watertight spaces.

The Coast Guard Maritime Safety and Security Team (MSST) San Diego Dive Team will support a Coast Guard Marine Board of Investigation inquiry into the sunken fishing vessel Destination. After better locating the wreck, imagery will be captured to help in the inquiry. Dive team members sanitize equipment in advance of the upcoming operations.

July 22, 2017 – Gulf of Alaska heading toward the Bering Sea. After a science team meeting, the RDC team began preparations for the upcoming unmanned underwater vehicle (UUV) evaluation. Coast Guard Cutter Healy crew members watch while RDC staff evaluate buoyancy and adjust the weights of the UUV.

July 21, 2017 – Seward, Alaska. Coast Guard Cutter Healy began its underway voyage today; among those on board are researchers from the Coast Guard Research and Development Center in New London, Connecticut, who will conduct the 2017 Arctic Technology Evaluation during the deployment. Over the past few days, the science team and Healy personnel have on-loaded the equipment needed for the evaluations, including a diver recompression chamber.

A solar panel is being put into place on an unmanned maritime system after unpacking it from shipping. The system was built by the RDC staff to assess potential roles of unmanned systems in Coast Guard missions in remote locations like the Arctic Ocean. An unmanned underwater vehicle and small unmanned aircraft system were also assembled while the team awaited departure.