June 7, 2023 —

Honored with 2022 Capt. Niels P. Thomsen Innovation Awards in a ceremony May 4, 2023, were, from left: Dr. James McCriskin of the USCG Academy ECG Screening Evolution 2022 team, which won in the Auxiliary Achievement category for ECG Screening of CGA Cadets to Detect Heart Anomalies; Jody Carman and Senior Chief Petty Officer Jason Neth of the D17 “Return to Ready” Pilot Program, which won in the Culture Change category for the “Return to Ready” Unit Leader Integrated Support Toolkit; Capt. Chad Brick of the Financial Management Wolfpack, which won in the Administration, Training or Support category for the Procurement Request Expedited Service System; Lt. Cmdr. Andrew Armstrong of the SFLC Additive Manufacturing Working Group, which won in the Science or Technology category for Programmatic Additive Manufacturing Implementation; and Lt. Steve Kidwell of the MIT – Research Laboratory of Electronics Graduate Students, which won in the Operations or Readiness category for Nonintrusive Load Monitoring for Shipboard Fault Detection. Not pictured: A team from the Research and Development Center, Defense Innovation Unit and C5I Service Center won the Cmdr. Joel Magnussen Innovation Award for Management for Use of OTAs and Rapid Prototyping to Solve the BCCS Problem. U.S. Coast Guard photo by Petty Officer 2nd Class Ronald Hodges.

“Innovation has never been more important than now.”

Adm. Steven Poulin’s words were meant as much for the group gathered at the Coast Guard Senior Leadership Conference as for the winners of the Capt. Niels P. Thomsen Innovation Awards that were being handed out. “We have to keep pace with the changing world,” the vice commandant said. “All of us need to sharpen our competitive edge. The status quo is no longer the best way.”

Poulin thanked the award winners for making the Coast Guard better through their projects. “You answered that call. You showed a willingness to take risks. You had the ingenuity and tenacity to look for new ways to complete our missions.”

The annual awards recognize innovative efforts by the Coast Guard workforce to increase efficiency or productivity or provide other process improvements. Their namesake is considered a legendary Coast Guard innovator; the chain stopper Thomsen developed in 2008 was credited with dramatically improving the safety of buoy tending operations for the Coast Guard. Thirty-seven projects were considered for the 2022 awards.

This year’s winners:

Science or Technology

TOP LEFT: Icebreaker, buoy and construction tender phone clips. BOTTOM LEFT: A wye gate handle being printed. RIGHT (1-4): An example of the part creation and implementation process with a Coast Guard member-designed 87-foot engine chockfast dam device. 1. A 3D computer-aided design model. 2. A draft of the engineering drawing. 3. The dam device being utilized during main engine change-out. 4. The final product after device removal.

Programmatic Additive Manufacturing Implementation by SFLC Additive Manufacturing Working Group

Cmdr. Jeff Smolik, Lt. Cmdr. Andrew Armstrong, Cmdr. Aaron Leyko, Lt. Stephen Kidwell, Lt. Ryan Miklosovich, Lt. j.g. Brandon Horacek, Chief Petty Officer Jonathan Zlocki, Tracy Byington, Kelly Hulon, Albert Hewitt, Kevin Grasson, Trigg McNew, Guy Tharpe, Michael Pohland and Robert Wagenmann.

The Surface Forces Logistics Center (SFLC) Additive Manufacturing Working Group was formed to increase capability and utilization of depot-level maintenance facilities by providing hard-to-source or prohibitively expensive parts that impact operational availability. Partnering with the Aviation Logistics Center, Research and Development Center and Department of Defense entities, the team formed a workflow allowing any member to submit an idea or issue to be solved via additive manufacturing (AM). In conjunction, the working group created a technically robust review and governance process which ensures responsible and responsive AM utilization. Leveraging Lt. Cmdr. Andrew Armstrong’s unique expertise, the group established SFLC’s first AM production center at no additional cost to the Coast Guard and provided the roadmap for implementation across the SFLC and Director of Operational Logistics enterprise.

“The Coast Guard has been working 3D printing for a while, but it has been very pocketed,” Armstrong said. “Now we have created a workflow and path for anyone to take advantage of. We have a 3D printing production shop, where we can make what is needed and send it where it is needed.”

Impact to USCG

Provides approval path for any Coast Guard member to solve a problem by submitting a request for a part, tool, jig, cover, training aid, etc. to be additively manufactured, greatly expanding the service’s naval engineering solution space. In addition, by coordinating with existing business rules and systems, the framework is built to provide any unit access to the approved solutions, which will save time and energy fleetwide. Currently, Industrial Production Facility New Orleans is printing approved parts for units.

Operations or Readiness

LEFT: Lt. Andrew Moeller installing monitoring equipment on a U.S. Navy littoral combat ship. MIDDLE: Lt. Brian Mills installing a bracket for a nonintrusive load monitor installation on Coast Guard Cutter Thunder Bay. RIGHT: Lt. Cmdr. Devin Quinn conducting research work on a 270-foot medium endurance cutter.

Nonintrusive Load Monitoring for Shipboard Fault Detection by MIT – Research Laboratory of Electronics Graduate Students

Lt. Andrew Moeller, Lt. Steve Kidwell, Lt. Isabelle Patnod, Lt. Cmdr. Devin Quinn, Lt. Cmdr. Thomas Kane, Lt. Cmdr. Gregory Bredariol, Lt. Brian Mills, Lt. Joseph O’Connell, Lt. j.g. Michael Bishop and Lt. j.g. Jacob Skimmons.

For several years a small cadre of Coast Guard officers has conducted research at the Massachusetts Institute of Technology (MIT) on nonintrusive load monitoring technology and its shipboard applications for fault detection and condition-based maintenance. A nonintrusive load monitor (NILM) measures the aggregate electrical power at a central utility point and extracts individual loads from the power stream, which allows the NILM to assess equipment health and predict potential failures before they are evident through traditional monitoring methods.

Kidwell explained that the NILM works much like a circuit breaker in a home, but instead of cutting the power, it generates data from the power stream to identify anomalies in how something is working. “The Coast Guard has a lot of old ships. And usually, we don’t know if something is broken until it is too late,” he said. “With this, we can observe a condition and determine it is trending toward breaking.” Fixing something before it breaks tends to take less time and be less expensive, he added.

Impact to USCG

This team collected data on numerous Coast Guard and Navy assets and was able to identify equipment failures not visible to the crew, such as faulty jacket water heaters, misaligned crankcase blowers and improper setting of low-temperature refrigeration compressor unloaders.

Administration, Training or Support

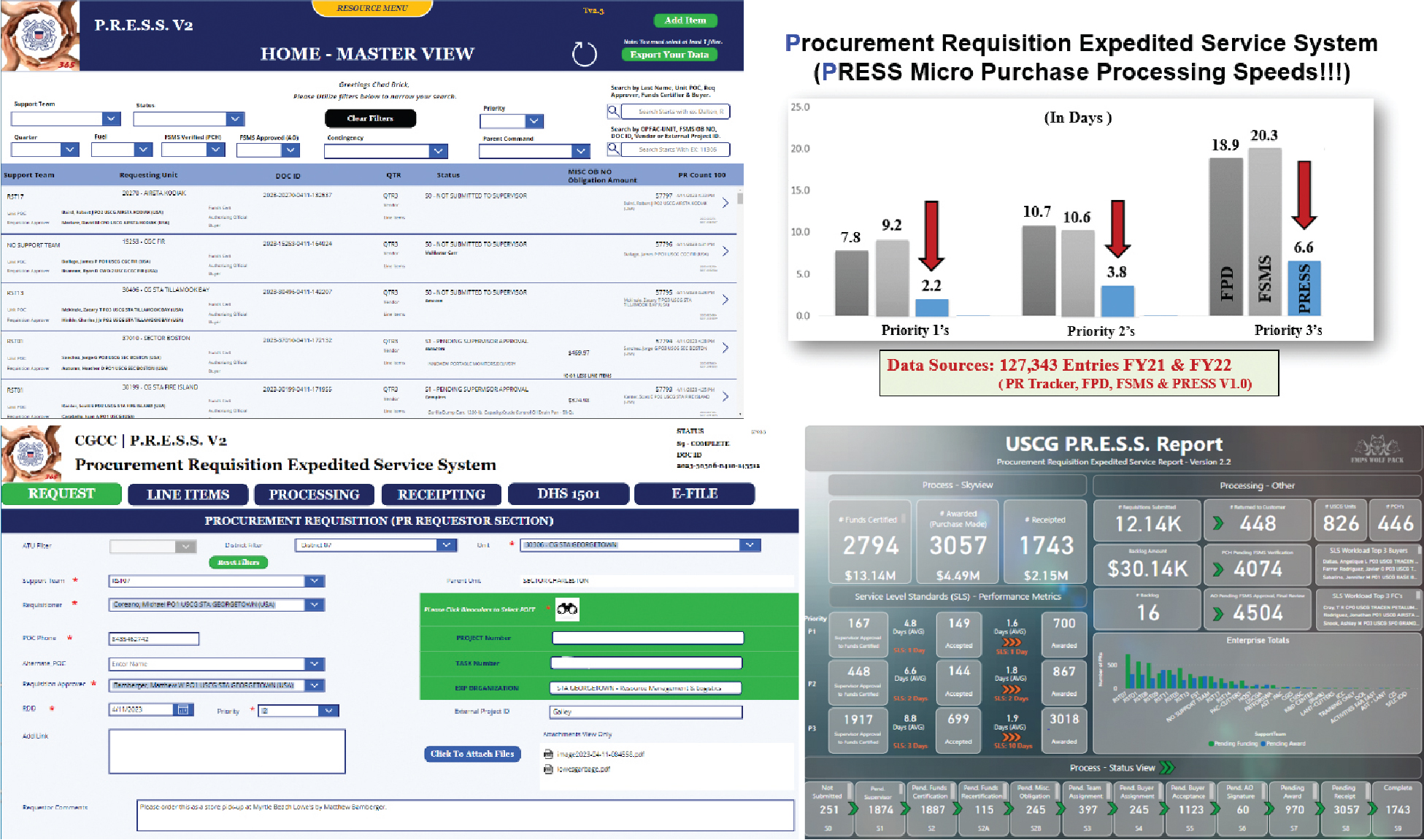

Clockwise from top left: PRESS home view. PRESS graph showing processing speeds. PRESS report. Tool picture.

PRESS – Procurement Request Expedited Service System by Financial Management Wolfpack

Capt. Chad Brick, Michael Fragano, Lt. Samuel Paone, Jeffrey Center, Rear Adm. Jon Hickey, Capt. Erich Klein, Capt. William Arritt, Capt. William Budovec, Cmdr. Thomas Crowley, Cmdr. Aaron Kowalczk, Chief Petty Officer Robert Thomas and Jennifer Souza-Madura.

Following the release of the Financial Systems Modernization Solution (FSMS) in fall 2021, it became immediately apparent that additional capability would be required to efficiently and effectively execute micro-purchases across the Coast Guard. The Financial Management Wolfpack, led by Capt. Chad Brick, built a workflow tool that leveraged bulk obligations to expedite micro-purchases while reducing workload and ensuring compliance. Over the course of several months, the Wolfpack built, tested and trained the system with over 7,000 users and the feedback from the user community was immediate and decisive – PRESS achieved its objectives of greatly reducing workload by making procurements faster and easier for customers; streamlining processes for service providers resulting in improved customer service consistent with Director of Operational Logistics Service Level Standards; providing full visibility and transparency regarding procurement status; and enabling integration with FSMS to ensure accurate accounting of obligations and full execution of the Coast Guard’s fiscal year 2022 appropriations.

PRESS was created to “fill the gap in the end-to-end process,” Brick said. “With PRESS, we were able to not just solve the problem but manage the data as well. Senior executives can see what is going on in real time.”

Impact to USCG

PRESS enabled over 100,000 micro-purchases totaling over $100 million, enabling full execution of the Coast Guard’s fiscal year 2022 appropriations. Currently, PRESS is implemented across all nine districts (regional support teams) for micro-purchasing and is relied upon every single day by thousands of individuals across the Coast Guard to obtain the parts, goods and services they need to get the job done and execute Coast Guard missions.

Culture Change

LEFT: The model adopted by the District 17 Return to Ready program recognizes roles and seeks to empower integrated action across the spectrum of behavioral health. Everyone is responsible for part of the health and performance of a shipmate, not just the individual or a mental health specialist. RIGHT: The Return to Ready decision aid/flowchart provides unit leaders with two initial options based on risk and urgency. Functional effectiveness is not always restored through a crisis intervention. Situations often benefit from preventive or follow-on coordination for more effective return to work plans, unit climate support and step-down care.

Return to Ready – Unit Leader Integrated Support Toolkit by D17 Return to Ready Pilot Program

Jody Carman, Capt. Leanne Lusk, Lt. Cmdr. Tom Wieland, Lt. Erin Bohner, Capt. Edward Hernaez, Cmdr. Will Johnson, Cmdr. Sarah Garrett, Cmdr. Marion Collins, Cmdr. Jose Gomez, Lt. Cmdr. Trevor Siperek, Lt. Brandt Peacock, Master Chief Petty Officer Phillip Waldron, Chief Warrant Officer Damon Lawson and Senior Chief Petty Officer Jason Neth.

It is often said that “90% of leadership time is taken up on 10% of people,” but how can one confirm that the effort is efficiently producing the best results for those 10%? The number of specialty resources available to the Coast Guard community is increasing, but the service has not taken steps to effectively integrate support for managers at their point of need. The sensitive nature of personal information, varied understanding of available resources and competing demands all contribute to role clarity challenges, a prevailing stigma surrounding behavioral health and missed opportunities to proactively address and follow through with harmful behaviors. A multi-disciplinary working group identified this need from unit leaders and met demand by defining the problem, then combining known best practices, existing Coast Guard programs and collaborative problem solving into a simplified toolset for leaders operating in District 17’s challenging and remote environment. This pilot program has shown Coast Guard culture, when given the right tools, is able to build upon strengths in risk management and empowerment of unit leadership to collectively evolve how the service prevents significant negative events, mitigates crises if they do occur and returns units, members and families to a ready state of functional effectiveness.

“The Coast Guard has many fantastic tools designed to help those in need, but programs often work independently,” Neth said. “Return to Ready brings them all to the table at the same time.” While the program is currently only available in District 17, its creators would like to see it expand Coast Guard-wide.

Impact to USCG

In 2022, the program handled more than 50 complex cases ranging from responses to emergencies, suicide prevention, workplace violence, medical and behavioral complex cases, domestic situations and direct impacts to cutter operations due to workforce issues. The toolkit has been credited with mitigating/preventing at least five cases that would have previously not received early intervention and resulted in high risk for suicide or workplace violence. In addition, each member effectively intervened and prevented from missed days at work or inpatient behavioral stays saves tens of thousands of dollars and hundreds of hours.

Auxiliary Achievement

The July 2022 electrocardiograms screening underway at the U.S. Coast Guard Academy.

ECG Screening of CGA Cadets to Detect Heart Anomalies by USCG Academy ECG Screening Evolution 2022

Dr. H. Elizabeth Noll, Dr. James McCriskin, Chief Petty Officer Edward Hodges, Chief Petty Officer Matthew Cuevas and Auxiliarist Bruce Buckley.

The July 2022 U.S. Coast Guard Academy ECG Screening Evolution was structured to allow for both remote and traditional onsite interpretation of cardiac electrocardiograms (ECGs) looking for abnormalities that can cause sudden cardiac death. This was a complex evolution, requiring detailed innovative information technology planning and secure data storage and transmission while ensuring compliance with privacy laws and cybersecurity to transmit ECGs to a remote location. Once interpreted, the secure encrypted ECGs were transmitted back to the Academy Clinic and uploaded to the new Coast Guard/Department of Defense Electronic Health Record MHS Genesis along with those read on site. Any appropriate cardiology evaluations and interventions were performed at Yale Cardiology. The evolution to help prevent sudden cardiac death was a success with remote ECG reading capabilities established for future use.

“Tapping in to the auxiliary is a real potential,” McCriskin said. “It is a huge brain trust of retired people.” As a cardiologist and medical officer with the auxiliary, McCriskin would like to see the program expand beyond the academy. “What about the enlisted at Cape May? And beyond? Everyone would benefit from this testing.”

Impact to USCG

This complex and innovative process to securely transmit and remotely interpret ECGs provided a cost-effective, timely and both privacy- and cyber-secure means to screen Coast Guard Academy cadets for abnormalities known to cause sudden cardiac death and allow for rapid preventive intervention.

Cmdr. Joel Magnussen Innovation Award for Management

Clockwise from top left: Lt. Cmdr. Anderson Ogg participates in land-based training of the boat crew communications system (BCCS). Maritime Safety and Security Team (MSST) San Francisco over the horizon (OTH) IV crews test the BCCS in the operational environment. Cmdr. Mike Nordhausen receives vendor training on board an OTH IV. An MSST San Francisco crewmember tests BCCS on a response boat-small II. MSST San Francisco members test the BCCS on board an OTH IV.

Use of OTAs and Rapid Prototyping to Solve the BCCS Problem by Research and Development Center, Defense Innovation Unit and C5I Service Center

Lt. Cmdr. Anderson Ogg, Cmdr. Mike Nordhausen, Maj. Sam Amedia (U.S. Air Force), Lt. Jonathan Anderson, Stacy Meister, Lt. Cmdr. Colin Boyle, Lt. Michael Jenkins, Lt. j.g. Jamie Higgins, Senior Chief Petty Officer Brian Milcetich, Chief Petty Officer Eric Wells, Petty Officer 1st Class Michael Barron, Charles Brown, Leslie Ranlet, Gregory Ducker, Katherine Kearney, Korey Barry, Mark Schneider, Myles Blanchard, Phil Lee and Robin Spelman.

Coast Guard small boats need a functioning boat crew communications system (BCCS) to safely and effectively perform their missions. The BCCS on the over the horizon (OTH) IV and response boat-small (RB-S) II are oftentimes not used by crews because they are rarely functional, difficult to repair and facing obsolescence. In July 2022, the Research and Development Center (RDC) partnered with the Command, Control, Communications, Computers, Cyber and Intelligence Service Center (C5ISC) to conduct a Commercial Solutions Opening through the Defense Innovation Unit (DIU). Less than 100 days later, the team competitively down-selected from 19 different companies and awarded prototype other transactions (OTs) to three different companies. This was the Coast Guard’s first use of OTs for prototypes. C5ISC began testing prototypes in September 2022, utilizing the C5ISC communications lab at Base Portsmouth.

“In this project, the innovation had to do with how we went about prototyping, testing and procuring, rather than the system itself,” Ogg said, using a procurement method outside of the Federal Acquisition Regulation. “This collaborative process with industry with rapid prototyping and testing is a model that can be used for many other things.”

Impact to USCG

The team anticipates procurement and fielding of its identified solution to occur 15 months from the start of prototyping. This project demonstrates a highly effective and fast prototype-to-acquisition pipeline. It buys down significant acquisition risk and ensures only the best-fit solutions are fielded. Most importantly, use of OTs and rapid prototyping to acquisition can be replicated and scaled for any tech area.

Related:

Video: Capt. Niels P. Thomsen Innovation Awards 2022

For information on Coast Guard R&D: Research, Development, Test and Evaluation Program page and Innovation Program page